Industry value

Deepwater cable solutions

With decades of expertise in aramid technology, we partner with leaders in the submarine power cable industry to deliver sustainable, high-performance solutions. Our aramid fibers provide the strength, flexibility, and underwater durability essential for deep-sea applications, ensuring operational efficiency and reliable, long-term performance in demanding environments.

Solutions

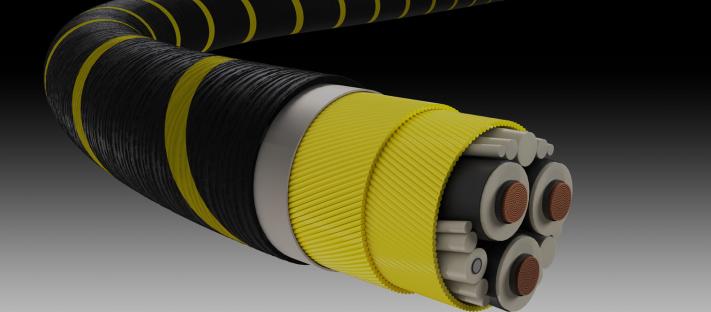

Submarine power cable reinforcement

Twaron® provides a high-performance solution for submarine cable projects, effectively reducing cable elongation and overall weight. This allows for longer cable segments to be laid in a single operation, increasing operational efficiency. With a superior strength-to-weight ratio, aramid-reinforced cables deliver the durability and reliability essential for safe, efficient operations. By choosing Twaron®, you can achieve faster, more efficient installations without sacrificing performance.

Product value

Twaron®-reinforced power cables for superior durability.

Twaron® offers superior cost efficiency and reliability for submarine cable projects in deep-sea applications beyond 1000 meters. Engineered to perform in extreme conditions, Twaron® provides the strength and resilience essential for dependable, long-term performance. By choosing this aramid product, you enhance project performance and reduce risk, supporting high-value installations with a focus on durability and sustainable performance.

Sustainability

Twaron® for cable installation efficiency

Twaron®-reinforced submarine cables are lighter than steel-reinforced alternatives, which may reduce the number of trips needed to transport them. This logistical advantage minimizes carbon emissions and cuts down on mid-project resupply, supporting both cost efficiency and environmental goals. With a low carbon footprint in production and recyclability options, aramid fibers deliver measurable sustainability benefits, helping partners meet eco-friendly objectives while maintaining high standards in installation success and operational efficiency. Learn more about Twaron® cable armoring by downloading our technical article.

Our expertise

Our research and development streams

We’ve organized our expertise to cover a variety of customer needs.

Trusted development partner

Our technical account managers provide personalized guidance from regional offices, helping customers select and implement the most effective aramid solutions for submarine cable applications. With additional support from our Research and Innovation Center (RIC) in The Netherlands, we deliver recommendations that meet each project’s precise needs for quality and performance.

Customized solutions and technical support

We conduct comprehensive material testing, assessing both primary and secondary properties to ensure aramid performance under challenging conditions, such as high temperatures, variable humidity, UV exposure, and seawater environments. This thorough process protects performance consistency even when processes are adjusted. We are currently the only major aramid producer systematically offering this level of testing.

Approver enabler process

Once an aramid solution is defined, we collaborate with partners and customers to achieve the required certification standards for new applications. Our continuous approver enabler process supports this certification by validating performance throughout each stage.

Certification process support

Our R&D team upholds strict quality standards. They oversee both products and processes to safeguard product integrity, defining quality benchmarks that our production quality teams apply to ensure every product meets the precise specifications required by our customers.

Quality guardianship

Our R&D team is the custodian of our quality standards. They scrutinize our products and processes to safeguard product quality. Our Research and Innovation Center staff design and set the standards of quality and supply these to our quality testing teams at production to ensure that the product ordered meets the precise specifications required by the customer.

Expert

Updates

New and upcoming

We regularly attend renewable energy events and publish news and stories about our innovative work with industry partners.

Connect with our aramid experts

Have technical questions about our aramid solutions, specifications, or applications? Fill out the contact form to speak directly with our material experts. We’re ready to provide detailed insights and discuss how our solutions can meet your specific needs.